MinÅsÃĐgirÃĄnyÃtÃĄsi rendszerÞnk folyamatos fejlesztÃĐsÃĐvel tÃķrekszÞnk a nulla hiba ÃĐs a 100%-os szÃĄllÃtÃĄsi pontossÃĄg elÃĐrÃĐsÃĐre versenykÃĐpes, hatÃĐkony gazdÃĄlkodÃĄs fenntartÃĄsa mellett.

Partner az ÃķntÃĐszetben

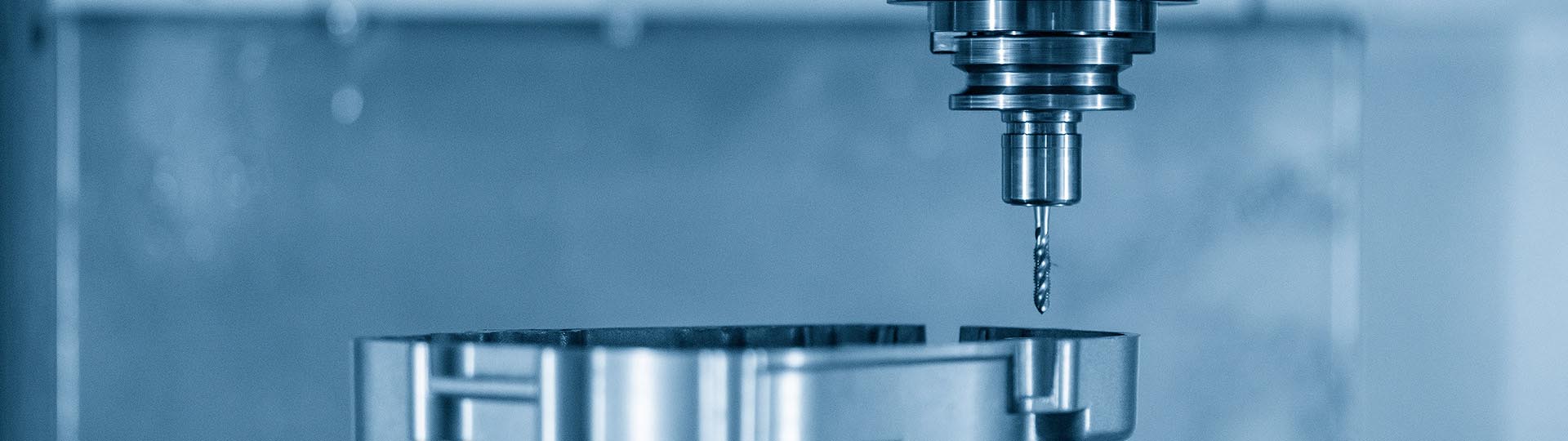

CÃĐgÞnk fÅ profilja nagypontossÃĄgÚ aluminium ÃĐs cink alkatrÃĐszek elÅÃĄllÃtÃĄsa az ÃķntvÃĐnytervezÃĐstÅl a szerszÃĄmgyÃĄrtÃĄson, ÃķntÃĐsen, megmunkÃĄlÃĄson, felÞletkezelÃĐsen keresztÞl az ÃķsszeszerelÃĐsig.

Ahol a minÅsÃĐg a legfontosabb!

SzÃĄmos iparÃĄgban megszerzett tÃķbb mint 60 ÃĐves szakmai tapasztalattal, magas mÅąszaki kompetenciÃĄval rendelkezÞnk a gyÃĄrtÃĄsi folyamat minden szakaszÃĄban.